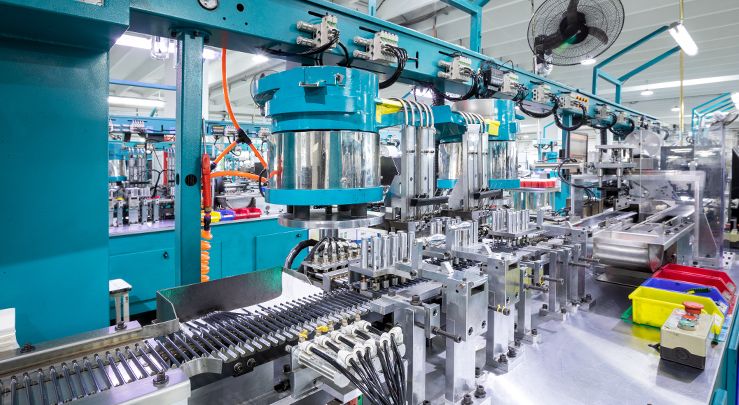

Injection workshop

To provide cool air solution to high temperature and sultry heat in injection molding workshop

———————————————————————————————————————

In most workshops in summer, the workshops are sultry and the temperature often reaches about 37 degrees. And the temperature will gets more higher if the workshops with dense personnel and many machines and equipment. What are the factors that cause the high temperature in the workshop?

1. Crowed people, poor ventilation in the workshop and poor air condition

2. The heat emitted by machinery and equipment during the production process leads to constant high temperature

3. The machine and equipment emit heat during the production process, resulting in constant high temperature

4. The workshop is not well ventilated, and the stuffy air cannot be discharged

5. The workshop has been closed for a long time and the air quality has dropped. It makes the air muddy.

The solution for the high temperature in the workshop is to install quality-guaranteed ventilation and cooling equipment. There are many common cooling equipment on the market, such as exhaust fans, fans, negative pressure fans, central air conditioners, etc. There are so many problems in the high-temperature workshops. To use the industrial mobile air-conditioners to ventilate and cool the workshop is a superior choice. First of all, it does not need to be installed and can be used when plugged in. Secondly, its cooling performance is very superior. For example, the exhaust fan equipment can only exhaust the air in the workshop, but it does not have a good cooling effect. However, the Dorosin industrial mobile air conditioner can be assigned to the position. Cooling can also discharge the turbid air to the outdoors, ventilate the workshop, and improve the air quality of the workshop. The smelly gas can be discharged outside, and the oxygen content of the indoor air can be strengthened, making the indoor air more cool and comfortable.

The solution for the high temperature in the workshop is to install quality-guaranteed ventilation and cooling equipment. There are many common cooling equipment on the market, such as exhaust fans, fans, negative pressure fans, central air conditioners, etc. There are so many problems in the high-temperature workshops. To use the industrial mobile air-conditioners to ventilate and cool the workshop is a superior choice. First of all, it does not need to be installed and can be used when plugged in. Secondly, its cooling performance is very superior. For example, the exhaust fan equipment can only exhaust the air in the workshop, but it does not have a good cooling effect. However, the Dorosin industrial mobile air conditioner can be assigned to the position. Cooling can also discharge the turbid air to the outdoors, ventilate the workshop, and improve the air quality of the workshop. The smelly gas can be discharged outside, and the oxygen content of the indoor air can be strengthened, making the indoor air more cool and comfortable.